How to Prevent, Predict, and Control an Industrial Electrical Fire

In the world of industry and commerce, where productivity and profitability often hang in the balance, the risk of an electrical fire can be a daunting prospect. For businesses that rely on complex electrical systems, the threat of an industrial electrical fire can pose significant challenges.

However, it’s not a scenario that should keep you up at night, especially if you’re associated with an industrial electrical company in the North Bay. The expertise of seasoned professionals can easily safeguard your business from the perils of electrical fires.

In this comprehensive guide, we will delve into the essential aspects of how to prevent, predict, and control an industrial electrical fire, safeguard your operations, and maintain the integrity of your business.

How to Prevent an Industrial Electrical Fire?

Preventing electrical fires is crucial for the safety of commercial spaces. Electrical fires are often caused by preventable issues, and taking steps to reduce the risk can go a long way in ensuring the safety of occupants and preserving property. Here are some tips on how to prevent electrical fires:

1. Regular Inspections

Routine inspections of your electrical system are essential. Hire a qualified electrician to inspect your home or facility at least once every few years, or as recommended by local regulations. These inspections can identify and address potential problems before they escalate into fire hazards.

2. Maintenance and Servicing

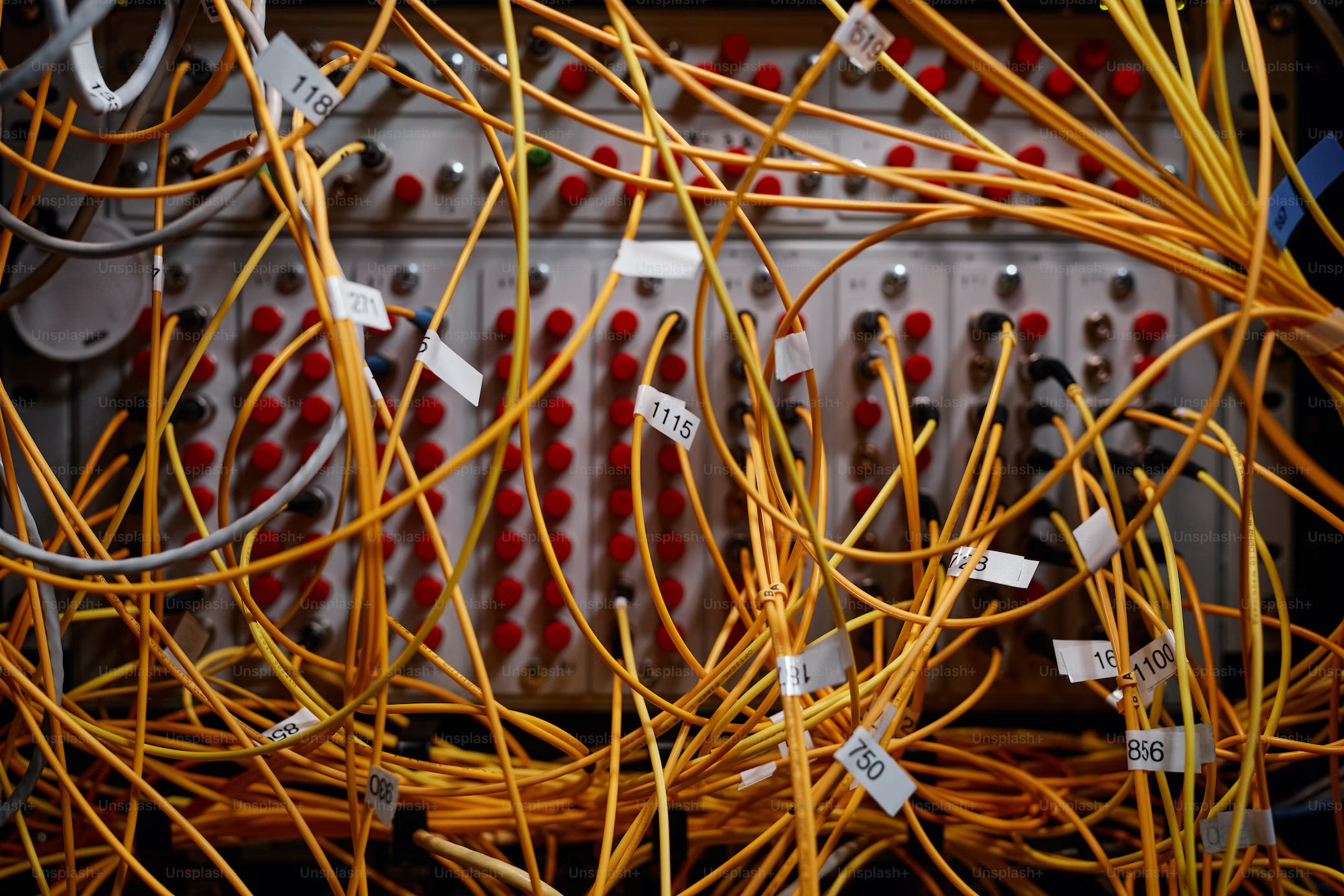

Regular maintenance and servicing of electrical equipment, machinery, and wiring systems are critical. Equipment that is well-maintained is less likely to experience electrical faults that could lead to fires. Implement a strict maintenance schedule and document all activities.

3. Load Monitoring

Keep a close eye on electrical load and usage patterns in your industrial facility. Unusual spikes or fluctuations in electrical demand, without corresponding changes in industrial processes, may indicate underlying issues that could lead to fire hazards.

4. Employee Training

Educate and train your employees on electrical safety practices. Ensure they are aware of the potential fire risks associated with electrical equipment and systems. Regular safety training and drills can instill a culture of vigilance and preparedness.

5. Use Ground Fault Circuit Interrupters (GFCIs)

GFCIs are designed to protect against ground faults and electrical shocks. Install GFCIs in areas where water or moisture is present, such as near sinks or in damp environments. They are a critical safety feature for industrial settings.

6. Arc-Fault Circuit Interrupters (AFCIs)

AFCIs are designed to detect and prevent electrical fires caused by arc faults. They are particularly important in industrial environments with complex electrical systems. Install AFCIs to protect against arc faults in your facility.

7. Electrical System Upgrades

Consider upgrading your electrical systems, especially if your facility operates with older wiring or components. Modernizing your electrical infrastructure with newer, safer technologies can significantly reduce the risk of electrical fires.

How to Predict an Industrial Electrical Fire?

Predicting industrial electrical fires is a complex task, but it is essential to take proactive steps to identify potential hazards and reduce the risk. While absolute prediction is challenging, a combination of monitoring, inspection, and awareness can help assess the likelihood of an industrial electrical fire. Here are some key steps to predict industrial electrical fires:

1. Monitoring Electrical Usage

Keep a close eye on your electrical load and usage patterns. Unusual spikes or fluctuations in electrical demand, without corresponding changes in industrial processes, may be indicative of underlying issues that could potentially lead to fire hazards.

Regularly maintain and service electrical equipment, machinery, and wiring systems. Well-maintained equipment is less likely to experience electrical faults that could lead to fires.

2. Analyze Historical Data

Analyze historical data on electrical faults and incidents in your industrial facility. Identifying recurring patterns or specific areas prone to electrical problems can help predict potential issues and take preventive measures.

3. Temperature Monitoring

Use temperature monitoring devices to keep track of the heat generated by electrical components. An abnormal increase in temperature can be a sign of an impending problem. These devices can provide early warning signs of overheating.

4. Early Warning Systems

Consider implementing early warning systems and monitoring solutions to detect electrical abnormalities and alert you to potential issues. These systems can be equipped with alarms that trigger when specific electrical parameters are exceeded.

5. Maintenance Logs and Records

Maintain comprehensive records of electrical maintenance, inspections, and repairs. These records can help identify trends and patterns that may indicate potential electrical fire risks.

How to Control an Industrial Electrical Fire?

Controlling an industrial electrical fire is a critical task that requires immediate action and adherence to safety protocols. Electrical fires in industrial settings can be particularly hazardous due to the presence of high-voltage equipment and complex electrical systems. Here’s a step-by-step guide on how to control an industrial electrical fire safely and effectively:

1. Prioritize Safety

The safety of individuals should always be the top priority. Ensure that everyone in the vicinity is alerted to the fire and is safe. Evacuate the area and call the fire department immediately. Do not attempt to control the fire if it’s spreading rapidly or uncontrollably.

2. Cut the Power Supply

If it can be done safely, the first step is to isolate the power source to the affected area. Shut off the power at the main electrical panel or circuit breaker. This will prevent the fire from being fueled by electricity.

3. Use a Class C Fire Extinguisher

Select the right type of fire extinguisher for the fire. For industrial electrical fires, use a Class C fire extinguisher specifically designed for electrical fires. These extinguishers contain non-conductive agents to suppress the fire without increasing the risk of electrical shock. Aim the nozzle at the base of the flames and sweep it side to side.

4. CO2 Fire Extinguisher

Carbon dioxide (CO2) fire extinguishers are another suitable choice for electrical fires. CO2 displaces oxygen and cools the fire, making it effective in suppressing electrical fires. Follow the same technique by aiming at the base of the flames and sweeping side to side.

5. Do Not Use Water

Never use water to extinguish an electrical fire. Water is an excellent conductor of electricity and can lead to electrocution and an even more hazardous situation. Using water on an electrical fire can also cause it to spread or intensify.

6. Cover With a Fire Blanket

If the fire is contained in a small appliance or equipment, you can use a fire blanket to smother the flames. Place the fire blanket over the burning area and let it cool down. Do not touch or move the blanket until you are sure the fire is completely out.

7. Sand or Baking Soda

In cases where a fire extinguisher is unavailable, you can use sand or baking soda to smother the flames. These materials are non-conductive and can help suppress the fire by cutting off its oxygen supply.

8. Fire Suppression Systems

In industrial or commercial settings, specialized fire suppression systems, such as clean agent systems or automatic sprinklers, may be in place to control electrical fires. These systems are designed to activate automatically when they detect a fire and should be used as intended.

9. Evacuate and Ventilate

Even after successfully controlling an electrical fire, it is crucial to evacuate the area and ventilate it to remove any remaining smoke and toxic fumes. Lingering fumes can be harmful and cause health issues.

Safeguarding your industrial facility against electrical fires is not just a priority, it’s a necessity. By adopting the preventive, predictive, and control measures we’ve discussed in this blog, you can significantly reduce the risk of electrical fires and ensure the continuity of your operations.

Whether you’re planning to implement preventive measures or require predictive maintenance services, Core Electrical Services, Inc. is your trusted partner. Our team of experienced professionals specializes in industrial electrical safety and maintenance.

You can count on us as your industrial electrical company in the North Bay. We are your trusted source for all your industrial electrical needs. To get started on securing your facility’s electrical systems, call us at (707) 687-5083 to schedule an appointment and ensure the safety and efficiency of your operations. Your peace of mind and the longevity of your business are always our top priorities.