5 Signs It’s Time to Replace Your Facility’s Electric Motor

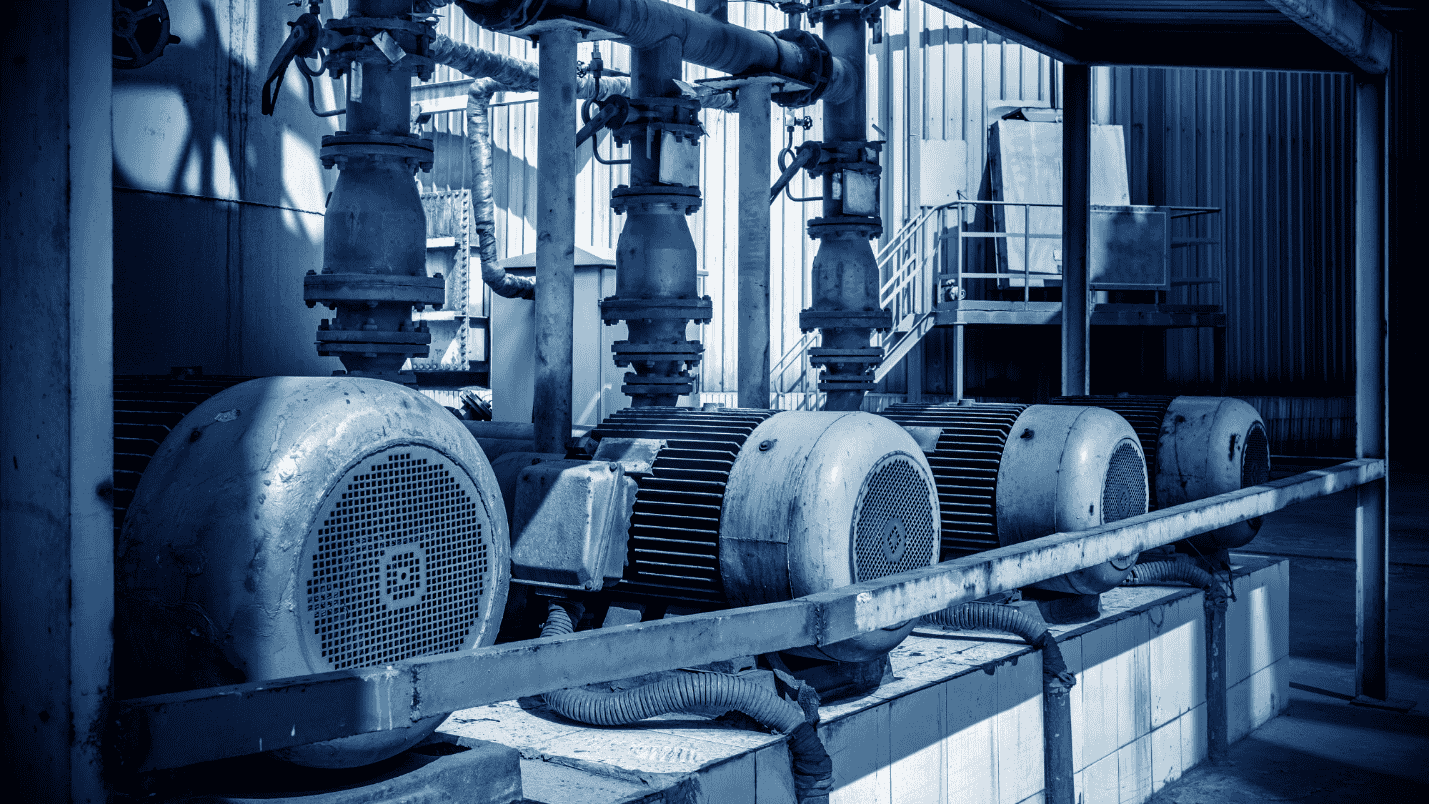

From HVAC systems to running production equipment, having a well-functioning electric motor is vital for the efficiency of commercial facilities. However, as essential as they are, electric motors don’t last forever. Over time, wear and tear can lead to decreased efficiency and potential safety risks, both requiring commercial electrical contractors in Sonoma County. Replacing a faulty motor before it fails entirely can save your business from costly downtime and repairs. Here, we’ll discuss the key indicators that signal it’s time to consider replacing your facility’s electric motor.

1. Decreased Efficiency and Performance

A noticeable drop in performance is often the first sign that your electric motor may need replacement. If you observe that the motor is struggling to reach its usual speed, torque, or output levels, it may be working harder than it should. This decline in efficiency could be due to aging components, insulation breakdown, or general wear, all of which lead to higher energy consumption.

2. Frequent Overheating Issues

Overheating is a critical sign that something is wrong with your electric motor and an important factor for avoiding an electrical emergency in the workplace. An overheated motor can result from various issues, including overloaded circuits, worn-out bearings, or insufficient ventilation. If the motor feels unusually hot to the touch or if it consistently trips its thermal protection devices, it’s time to evaluate whether repairs or a full replacement is the better course of action.

3. Unusual Sounds or Vibrations

While all electric motors produce some level of noise, unusual or excessive sounds indicate trouble. Grinding, humming, or screeching noises can signal problems with internal components, such as bearings or rotor misalignment. Vibrations often accompany these noises and can signify unbalanced loads or loose parts. To prevent compromising the safety and structural integrity of any surrounding equipment, its best to find a reliable commercial electrician near you to inspect the noise.

4. Rising Maintenance and Repair Costs

If you find yourself frequently repairing the same motor, it may be more economical to replace it. As motors age, components wear out more quickly, and repairs become less effective at restoring optimal performance. Repeated repairs also add up in terms of both labor and parts, so it’s often more cost-effective in the long run to invest in a new motor that will deliver consistent reliability.

5. Increased Operating Costs

Older motors tend to consume more energy, leading to higher utility bills. In commercial facilities, this can add up quickly, especially if you have multiple motors operating simultaneously. If you notice a significant rise in your facility’s energy costs, outdated motors may be the culprit. Making your commercial electrical system more energy efficient can yield substantial savings over time and may qualify for energy efficiency rebates.

CORE Electrical – Upgrade Your Commercial Electrical Motor

Don’t let a failing motor disrupt your business. Contact CORE Electrical Services today or call us at (707)687-5083 to schedule an evaluation and ensure your facility’s electric motors are in top condition. Connect with us to explore how our commercial electrical contractors in Sonoma County can help keep your commercial operations running smoothly and efficiently.